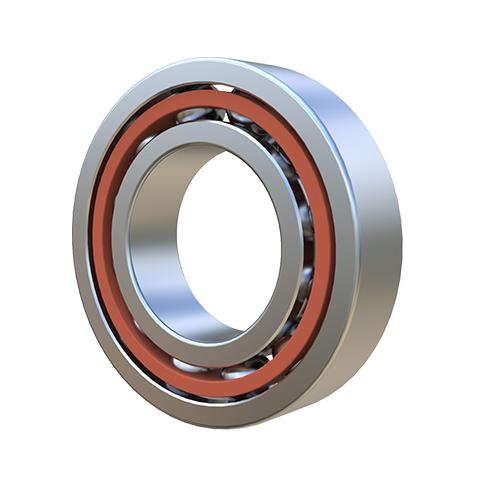

Angular contact ball bearing

● Product description

Cage: There are three types of retainers. Bakelite retainer, iron retainer, bronze retainer

Purpose: This kind of bearing has higher requirements for bearing accuracy and speed, and is mostly suitable for spindle bearings, engraving machines and other equipment

● Product features:

Angular contact ball bearings are especially suitable for bearing synthetic loads, that is, simultaneous radial and axial loads, and the axial load bearing capacity increases with the increase of the contact Angle α. The contact Angle is defined as: the Angle between the common normal and the radial plane of the bearing between the contact point of the rolling body and the raceway or the midpoint of the contact line is called the bearing contact Angle, and the load is transferred from one raceway to another raceway along this connection. For a single row of bearings, the contact Angle size can be identified by different code suffixes. The production of angular contact ball bearings include: single row angular contact ball bearings, double row angular contact ball bearings, four point contact ball bearings

Structural characteristics of single row angular contact ball bearings: single row angular contact ball bearings can only withstand the axial load of unidirectional action. Under the action of radial load, there will be an axial force in the bearing, which needs to be adjusted by a reverse force. Therefore, such bearings generally need to rely on a second bearing to balance. Single row angular contact ball bearings can be loaded with more steel balls, so that the bearing has a higher bearing capacity. The contact Angle is 15°, 25° and 40°, and the suffix code is C, AC and B respectively. Single row angular contact ball bearings include non-separation type and separation type. Non-separated bearings are divided into standard, high-speed and ultra-high-speed three series according to different applications; The inner and outer rings of the separate bearing can be installed separately, and are only used in parts with limited installation positions such as magneto, which is also called magneto bearings. Non-separated bearing cage, inner ring guide fiber reinforced phenolic resin cage is standard structure, not indicated in bearing code. When other cages are used, indicate with the corresponding suffix code: TA: outer guide fiber-reinforced phenolic resin cage TN: Reinforced nylon 66 mold cage M: Brass car cage Separate type bearings (i.e., magneto bearings) mainly use reinforced nylon 66 mold cage, if required, can also be provided with brass plate stamped cage bearings. Bearings with reinforced nylon 66 mold cages are suitable for most applications and can operate at -30℃ to 120℃.

Four point contact ball bearing

The four-point contact ball bearing is a single row angular contact ball bearing with raceways designed to withstand bi-directional axial loads. Such bearings require less axial space than double-row bearings. The four-point contact ball bearings listed in the following table have a contact Angle of 35°, and the inner ring can be divided into two pieces, which can hold a larger number of steel balls and therefore have a larger load capacity. The bearing is separable, that is, the two pieces of the inner ring and the outer ring with the ball and cage assembly can be installed separately.

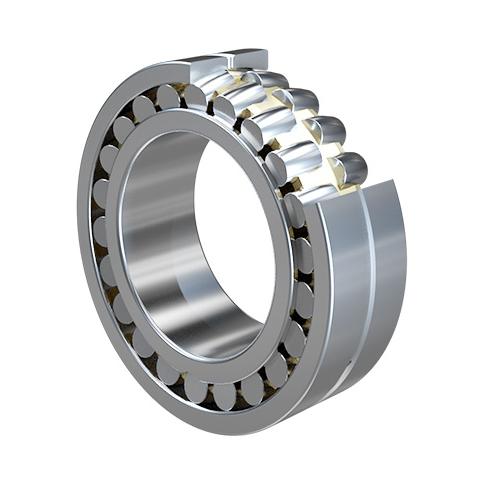

Double row angular contact ball bearing

Double-row angular contact ball bearings are similar in design to two single-row angular contact ball bearings arranged back-to-back. But the width is slightly narrower than two single-row bearings, and the contact Angle is 30°. This kind of bearing has good rigidity, can withstand overturning moment, and is a non-separated structure. The design types available are shown below. Double row angular contact ball bearings mainly have the following designs:

1, one side with a ball gap, the design can use a larger, more steel ball, can withstand a larger radial load and one-way axial load, generally using steel plate stamping or car brass solid cage, suitable for low speed occasions.

2, without the ball filling notch, the design can withstand bi-directional equal axial load, the use of glass fiber reinforced nylon 66 cage or steel plate stamping crown cage, can make the bearing heat less, so the operating temperature is low, this advantage is very important in high-speed operation.

3, with dust cover or sealing ring, the design can provide double or single side with dust cover (non-contact) or sealing ring (contact). These sealed bearings are filled with anti-rust lubrication dual-purpose grease, no special requirements, lithium 2# grease, operating temperature -30 to +100℃. With permanent lubrication, no maintenance. It should not be heated or cleaned before installation. Bearing with dust cover is mainly used for inner ring rotation, outer ring rotation, if the speed exceeds a certain value, there will be the possibility of grease overflow. In bearings with sealing rings on both sides, the sealing lip touches the groove on the shoulder of the inner ring. The sealing ring is made of oil-resistant and wear-resistant rubber, reinforced with steel sheets. The permissible operating temperature of the seal is -40 to +120 ° C. The sealing outer ring is clamped in the groove of the outer ring shoulder, and the outer ring is sealed without deformation. The oil seal lip creates a slight sealing pressure on the inner ring. Under harsh conditions, such as very high speed or operating temperature, the inner ring may leak grease. If the bearing configuration does not allow grease leakage, special design measures may be required.