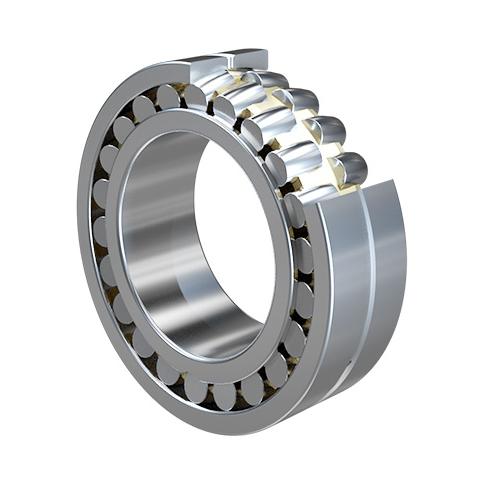

Self-aligning roller bearings

● Product description

Cage: Model suffix CA,MA,MB,CNA suffix letters indicate copper retainer CC, E, iron retainer

Clearance: Standard aligning roller bearings have normal radial internal clearance. However, almost all bearings in practical applications are suitable for C3 clearance supply, and some even reach larger clearance C4. Some sizes can be supplied with less than regular grade C2 clearance

Tolerances: aligning roller bearings with cylindrical or tapered inner holes have common tolerances

Temperature: Standard aligning roller bearings undergo special heat treatment, and will not undergo any unauthorized dimensional changes when the operating temperature is higher than +200℃

Application: Bearings are mainly used in mining, chemical industry, wind power, heavy machinery, metallurgy, steel, construction and other large machinery and equipment.

● Product features:

Aligning roller bearings are bearings with two rows of raceways in the inner ring, spherical raceways in the outer ring, and drum shaped rolling body. The center of the raceway surface of the outer ring is consistent with the center of the bearing, and the two raceways of the inner ring are tilted to an Angle relative to the bearing axis, and the bearing can be automatically aligning, so it is not easy to be affected by the alignment error of the shaft and the axle box seat or the bending of the shaft. In addition to bearing radial load, bearing can also withstand a certain two-way axial load, suitable for bearing vibration, impact load occasions. Aligning roller bearings are equipped with a large number of long and symmetrical large diameter rollers that can withstand concentrated loads. The special structure of the raceway and the best quality of the raceway surface ensure that the self-aligning roller bearings, type C and CA bearings have minimal friction. Compared with traditional self-aligning roller bearings, these bearings operate at lower temperatures, can withstand heavier axial loads, or can reach higher speeds. HRB aligning roller bearings with cylindrical or tapered inner holes. The 240 and 241 series bearings have a tapered inner hole taper of 1:30 (rear code K30), while other bearings have a tapered inner hole taper of 1:12 (rear code K).

C and EC type design

This type of bearing has symmetrical rollers with a stamped steel plate cage. The guide ring is centered on the inside. Type EC bearings use reinforced rollers to increase load capacity. The surface finish of the C-bearing roller and raceway is optimized to help guide the roller and reduce friction.

CA and ECA type design

This type of bearing has a symmetrical roller and an inner ring with a guard. The guide ring is centered from the inside between two rows of rollers. The cage is an integrated brass or steel cutting frame. The CA and ECA models have a Type C surface finish, and the ECA models have reinforced rollers for increased load carrying capacity.

Oil tank and oil hole

For effective lubrication, the standard type alters roller bearing outer ring with annular oil groove and three oil holes, except for Type C bearings with an outer diameter less than 150mm or 180mm (depending on the series) and all series 213 bearings. The suffix W33 is used to indicate that the outer rings of type C, EC, CA and ECA bearings have oil grooving and oil holes.