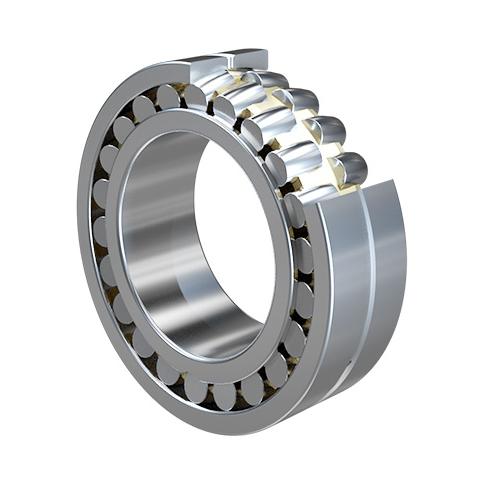

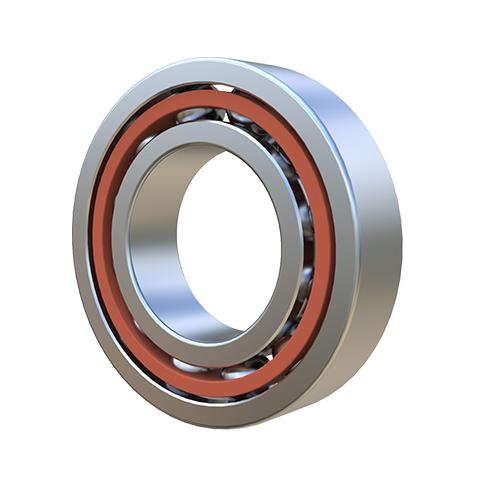

Radial thrust ball bearing

● Product description

Cage: The cage used for thrust ball bearing is steel stamped cage and copper cage

Tolerance: The standard product of thrust ball bearings is P0 tolerance. If necessary, we can provide customers with P6, P5 and P4 precision products

Application: Used in automobile, mining, metallurgy, plastic machinery and so on

● Product features:

Thrust ball bearings are divided into two categories: one-way thrust ball bearings and two-way thrust ball bearings

One-way thrust ball bearing:

One-way thrust ball bearings are separable bearings. It consists of a shaft ring, a seat ring and a combination of a ball and a cage. Easy to install and remove. The ring that is closely matched with the shaft is called the shaft ring, and the gap with the shaft is called the seat ring. One-way thrust ball bearings can only bear one-way axial load, can not bear any radial load, can be single-direction axial positioning of the shaft. Since radial movement between the shaft and the housing hole cannot be restricted, the limit speed is low. When the axis of the shaft and the bearing seat hole do not coincide or the bearing support surface is not perpendicular to the axis, it will cause premature bearing damage. If this is the case, a thrust ball bearing with a spherical seat can be used to compensate for the Angle error between the bearing box and the ball.

Two-way thrust ball bearing:

Two-way thrust ball bearings are separable bearings. It consists of a shaft ring with grooves on both sides, two seat rings, two balls and a cage assembly. Two-way thrust ball bearings can withstand the axial load of two-way action, and can not bear any radial load. Therefore, the axis can be bidirectional axial positioning.

The seat ring and ball cage assembly are identical to the corresponding one-way bearings