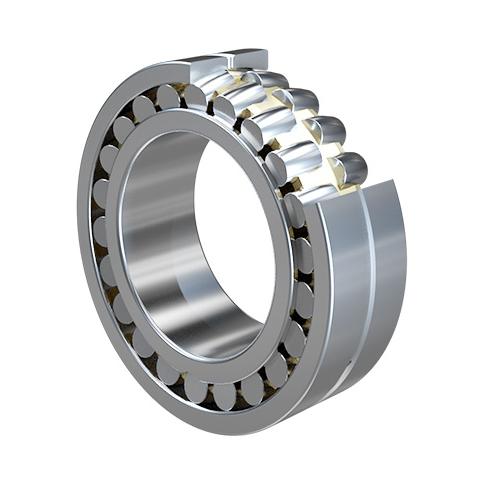

Class 0 deep groove ball bearings

● Product description

Cage: Deep groove ball bearings generally use steel plate pressed cage or brass solid cage. When the outer diameter is less than 400 mm, the steel stamping cage is used without a rear code, and when the outer diameter is greater than 400 mm, the brass solid cage is used without a rear code

Clearance: Standard deep groove ball bearings have C2, CN, C3, C4 and C5 internal clearance, all in line with GB4604

Tolerance: Standard deep groove ball bearings have ordinary grades, all in line with GB307.1

Uses: Deep groove ball bearings can be used in transmission, instrumentation, motor, household appliances, internal combustion engines, traffic vehicles, agricultural machinery, construction machinery, construction machinery, roller skates, yo-yo ball and so on

● Product features:

Deep groove ball bearings mainly bear radial loads, but also can bear radial loads and axial loads at the same time.

The structure of deep groove ball bearings is simple, and it is easy to achieve higher manufacturing accuracy than other types, so it is easy to form a series of mass production, and the manufacturing cost is also low, and the use is common. In addition to the basic type of deep groove ball bearings, there are a variety of variant structures, such as: deep groove ball bearings with dust cover, deep groove ball bearings with rubber seals, deep groove ball bearings with stop grooves, deep groove ball bearings with large load capacity of ball notches, double row deep groove ball bearings.

Deep groove ball bearing is a representative rolling bearing, widely used. It is suitable for high speed and even high speed operation, and is very durable and does not require frequent maintenance. This kind of bearing has the advantages of small friction coefficient, high speed limit, simple structure, low manufacturing cost and easy to achieve high manufacturing accuracy. The size range and form are varied, and it is used in precision instruments, low noise motors, automobiles, motorcycles and general machinery industries, and is a widely used class of bearings in the machinery industry. Mainly bear radial load, can also bear a certain amount of axial load. When the radial clearance is large, the axial load capacity increases, and the contact Angle is zero when the pure radial force is borne. With axial forces, the contact Angle is greater than zero. Generally use ram wave cage, car solid cage, sometimes also use nylon frame. After the deep groove ball bearing is installed on the shaft, the axial displacement of the shaft or the housing in two directions can be limited within the axial clearance range of the bearing, so the axial positioning can be made in both directions. In addition, this kind of bearing also has a certain aligning ability, when relative to the shell hole tilt 2 '~ 10', it can still work normally, but it has a certain impact on the bearing life. Deep groove ball bearing cages are mostly steel plate stamping wave cages, and large bearings are mostly made of metal solid cages.

Deep groove ball bearings are commonly used rolling bearings. Its structure is simple and easy to use. It is mainly used to bear radial load, but when the radial clearance of the bearing is increased, it has a certain angular contact ball bearing performance and can bear the combined radial and axial load. When the speed is high and it is not suitable to use thrust ball bearings, it can also be used to withstand pure axial load. Compared with other types of bearings with the same size and specification of deep groove ball bearings, the friction coefficient of such bearings is small and the speed limit is high. However, it is not shock resistant and is not suitable for heavy loads.